A client brought us their 1994 Jeep Cherokee XJ for a few modifications. They are wanting to move the rear axle back 3″ by way of some Ruff Stuff 3″ perches that are also u-bolt eliminators. And in order to do so they will be needed some light fender work. At the same time we will be adding in front frame stiffeners by TNT Customs. And to top it all off we will be adding an exo cage to it. We were given a little leeway into the design, but are not allowed to have any tubes in the passenger compartment. So we will be doing everything we can to beef it up since we won’t be able to add in that major structure component for lateral support.

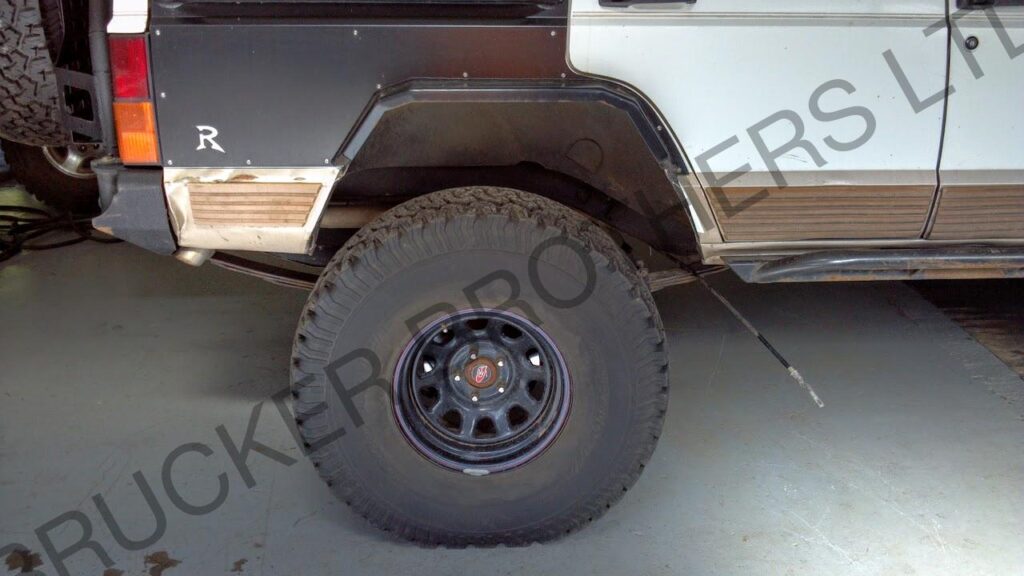

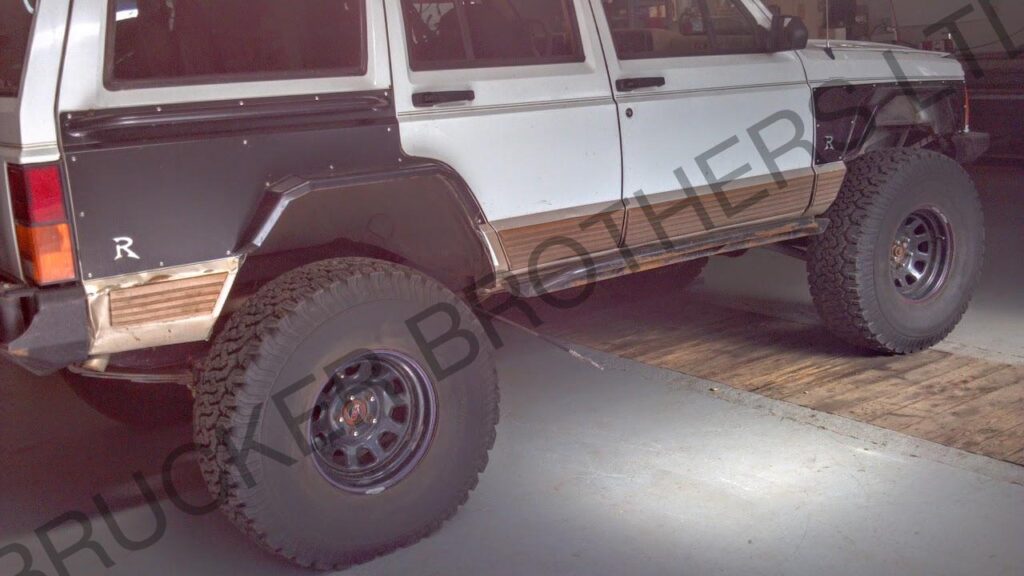

We start off with a look at the subject as it arrived at the shop:

Before we can do anything else, we need to get the rear axle moved back into it’s new home. In order to accomplish this we are going to be using these new spring perches from Ruff Stuff that the client brought us. They allow the axle to be positioned 1″ farther back from stock, 2″ farther back, or 3″ farther back. We will be setting the axle in the 2-3″ range. In addition to moving the axle back, they are also u-bolt eliminators. This will help create a smooth sliding surface on the bottom of the axle. We will also be moving the shock mounts to the top of the axle tube to aid in this.

We put the vehicle on stands and remove the rear axle. Then position it on the fab table to pull measurements before bracket removal.

Putting new perches allows us to set the new pinion angle with the perches and eliminates the need for any shims. We take all our measurements and calculate for the axle move and the removal of the existing shims. We then remove the shims from the leaf packs and cut the brackets off the axle.

With clean axle tubes we layout and then tack weld into position the new perches.

In order for the top spring plates to fit the center spring bolt/pin, we had to enlarge the holes a hair.

Half of the supplied bolts for the perches were to long and actually hit the axle tube, so for now we use a couple washers to shim them and will replace with shorter bolts once ordered in.

With the axle back into position, we reinstall the wheels and tires to get a good look at how much fender work will actually be needed.